An engineering business has to manage a complex situation of supplying parts for first time construction as well as ensuring spare parts are available for repairs and refurbishments. The demand profiles for each item are therefore complex to manage, but supporting both parts of the business with high levels of service is vital to the success of the business. The business was achieving inventory availability but struggling to keep inventory levels under control, so the challenge was to find inventory reduction opportunities.

Applying segmentation methodology to spare parts supply management

Challenge

Approach

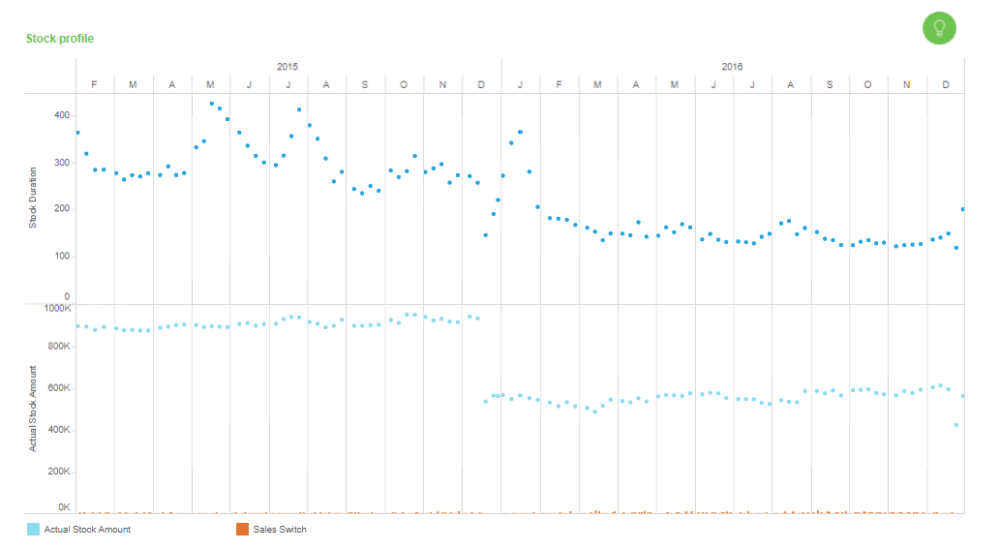

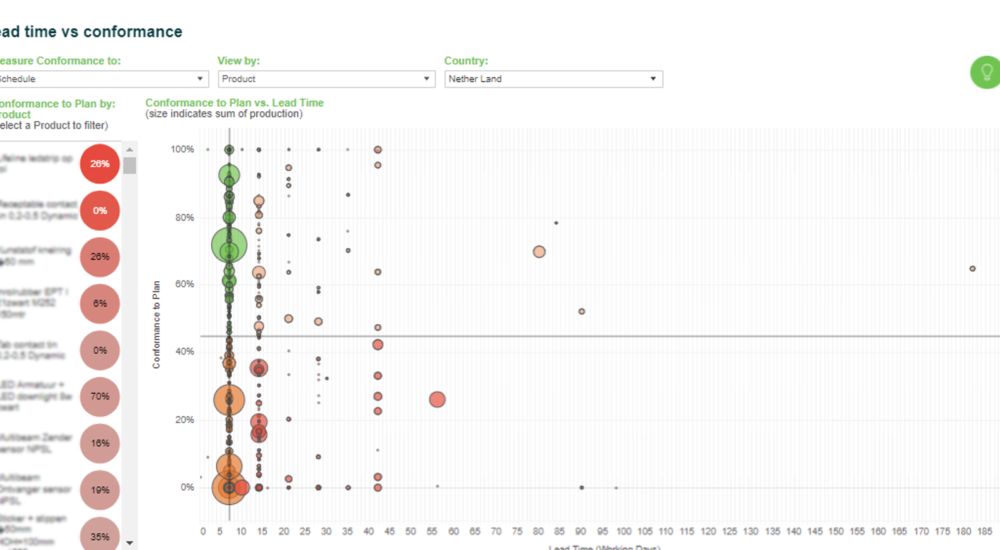

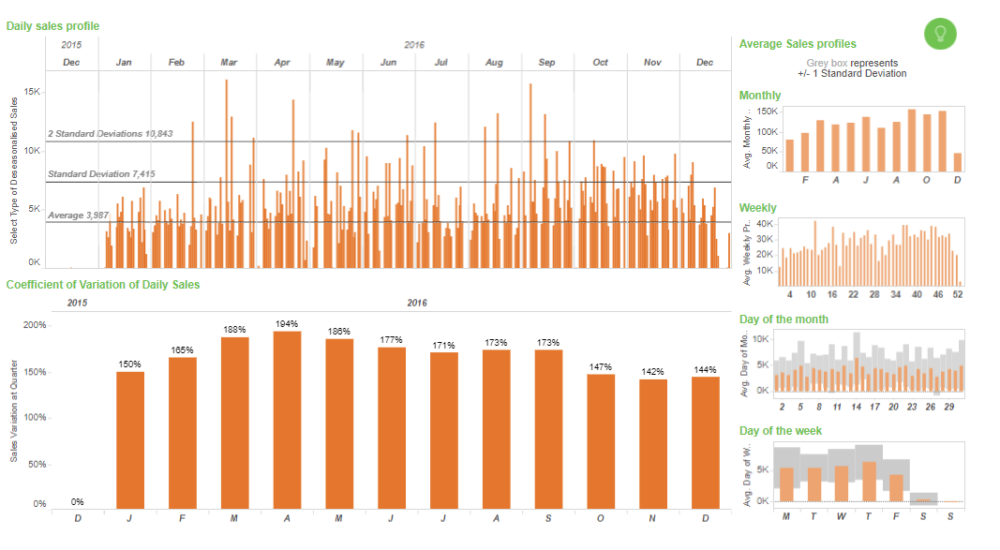

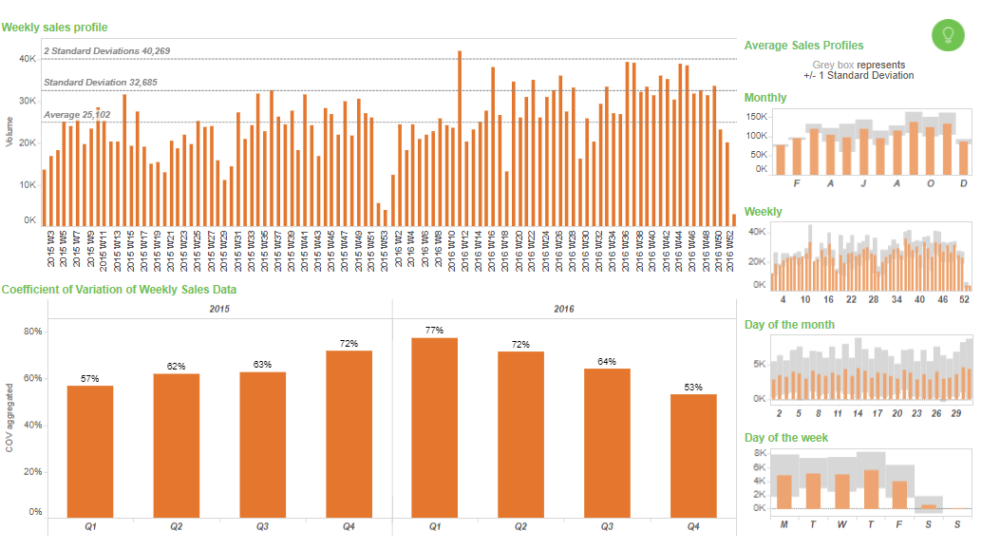

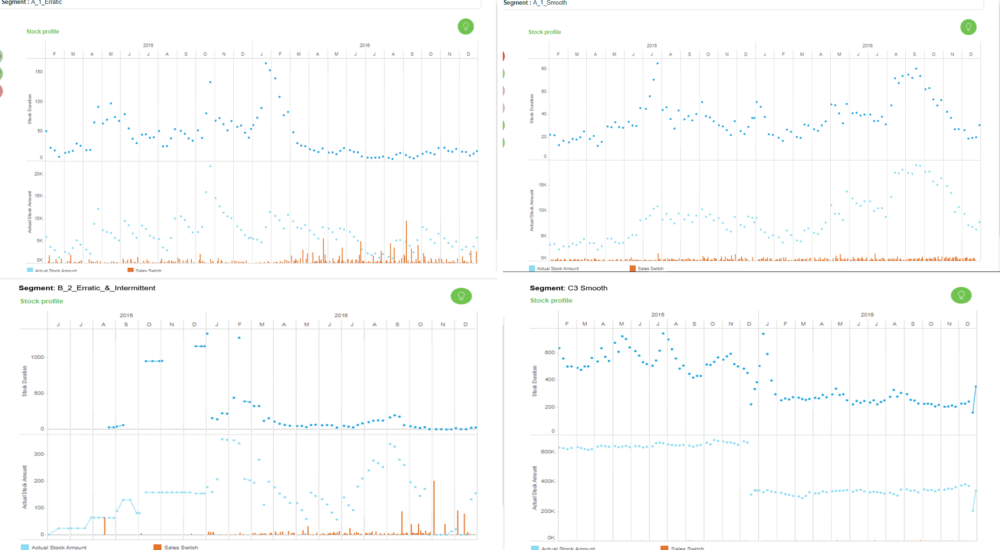

The team used SupplyVue to segment the demand for parts into 36 granular boxes of like types of demand and analyse the flow of parts through the supply chain for each of the segments, analysing the replenishment policies and parameters and the resulting inventory levels and availability.

Assessment

Description

Stable and consistent weekly demand

Short and reliable lead times

High inventories across all segments

Lack of policies at segment level

Future State

Using SupplyVue the team used the segments to model a number of replenishment scenarios with different replenishment cycle times and different order quantity rules. The baseline inventory cover was 127 days for the whole portfolio. Scenario 3 based on Fixed order cycle (FOC) replenishment for the faster moving items and fixed order quantity (FOQ) for the slower moving items, results in a modelled inventory cover of 27 days and scenario 5, Fixed Order Quantity for SKUs based on Minimum order quantities, resulted in a modelled holding of 36 days.

In addition to the inventory reduction, both scenarios modelled at 99% availability for all SKU and showed a pattern of demand on the manufacturing department and suppliers that was significantly more stable and predictable. This stability will provide knock on benefits.