Supply chain collaboration and optimisation has the potential to solve many of today’s most pressing manufacturing challenges.

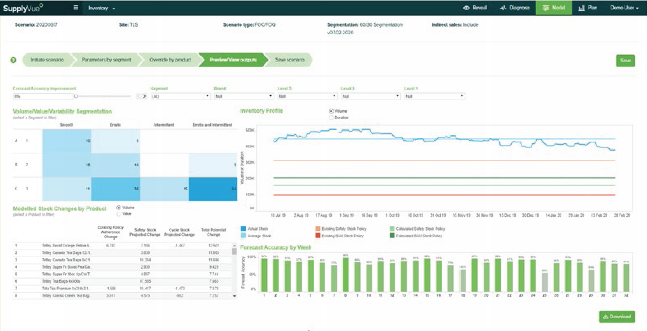

Data is the key to unlocking many of these benefits. WMG’s Supply Chain Research Group (SCRG), led by Professor Jan Godsell, worked with SupplyVue Analytics to develop their supply chain analytics software, SupplyVue. The tool assesses a business’s end-to-end supply chain, including production scheduling, planning and inventory management, and uses this to suggest ways to optimise the supply chain.

We spoke to John Burdett, Global Operations Director for Tata Consumer Products Ltd. (TCPL). We learned how they mobilised the insights of SupplyVue for their tea supply chain into the Canadian market, and worked successfully through one of the biggest global crises in recent memory, the COVID-19 pandemic.