Predicting demand in food and drink retail is notoriously difficult, and never more so than during the COVID-19 pandemic.

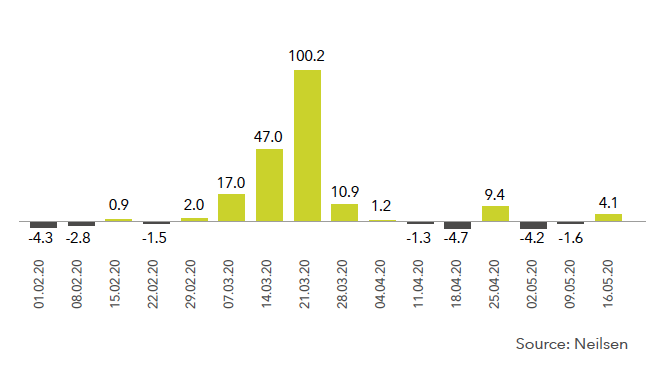

In March and April 2020, panic buying in supermarkets in the UK, caused a spike in demand of up to 100%. Many manufacturers and distributors simply struggled to meet demand, which caused many basic products like toilet rolls, tea and pasta to disappear from the shelves.

John Burdett, Global Operations Director for Tata Consumer Products Ltd. (TCPL),leads the end-to-end supply chain operations for TCPL’s tea and coffee businesses. Tata Consumer Products Limited is a focused consumer products company uniting the principal food and beverage interests of the Tata Group under one umbrella. Its key beverage brands include Tetley in UK, Eight O Clock Coffee in USA and Tata Tea in India.